HOW IT WORKS?

The power flushing pump is connected into the heating system, wherever most practicable

The machine acts as a pumps which is more powerful than your central heating pump, mixed with a chemical, the flushing pump will dislodge and mobilise deposits and corrosion.

Once the corrosion and sludge deposits have been loosened and mobilised, fresh clean water is forced through the heating system, pushing the contaminated water out. During the process, radiators are individually flushed, without removing or disconnecting them from the system, by directing the full output of the pump through each radiator separately.

At the end of the flushing process, the system is filled with fresh clean water and reinstatement of the system to normal operation takes only a few minutes.

Power flushing can be applied to all systems although the set up for conventional vented systems is a little more involved.

System flushing will not remedy design or mechanical faults.

However it will improve the performance of an old system and output of older radiators. It has been proved to increase the life of boilers and reduce the instances of heat exchange blockage the classic symptom of which is the water from a combi boiler is hot then cold then hot.

The power flushing pump is connected into the heating system, wherever most practicable.

The machine acts as a pumps which is more powerful than your central heating pump, mixed with a chemical the flushing pump will dislodge and mobilise deposits end of the flushing process, the system is filled with fresh clean water and reinstatement of the system to normal operation takes only a few minutes.

The power flushing pump is connected into the heating system, wherever most practicable

The machine acts as a pumps which is more powerful than your central heating pump, mixed with a chemical the flushing pump will dislodge and mobilise deposits and corrosion.

Once the corrosion and sludge deposits have been loosened and mobilised, fresh clean water is forced through the heating system, pushing the contaminated water out. During the process, radiators are individually flushed, without removing or disconnecting them from the system, by directing the full output of the pump through each radiator separately.

At the end of the flushing process, the system is filled with fresh clean water and reinstatement of the system to normal operation takes only a few minutes.

Power flushing can be applied to all systems although the set up for conventional vented systems is a little more involved.

System flushing will not remedy design or mechanical faults.

However it will improve the performance of an old system and output of older radiators. It has been proved to increase the life of boilers and reduce the instances of heat exchange blockage the classic symptom of which is will not remedy design or mechanical faults.

However it will improve the performance of an old system and output of older radiators. It has been proved to increase the life of boilers and reduce the instances of heat exchange blockage the classic symptom of which is the water from a combi boiler is hot then cold then hot.

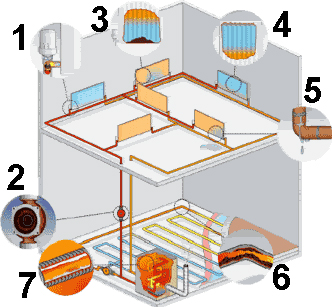

- Blockage in radiator valve Leading to incorrect operation of valve, no flow in radiator

- Pump seizure and failure the abrasive and magnetic properties of black oxide sludge increase shaft and bearing wear in pumps causing them to stick or fail.

- Cold spots - The familiar cool low central area of a radiator indicates a build-up of black sludge sediment that restricts flow and reduces heat.

- When the top of a radiator is cold during operation, either air or hydrogen is to blame. Hydrogen gas builds up as a by-product of electrolytic corrosion and is flammable (due caution is required).

- Pinhole leak Water damage

- Black sludge in underfloor pipework Reduced flow or blockage in pipework

- Scale (limescale/iron oxides) in boiler Leading to reduced efficiency, increased emissions, higher fuel bills and boiler noise